Plastic Pallet Manufacturing Plant Project Report 2025 Edition

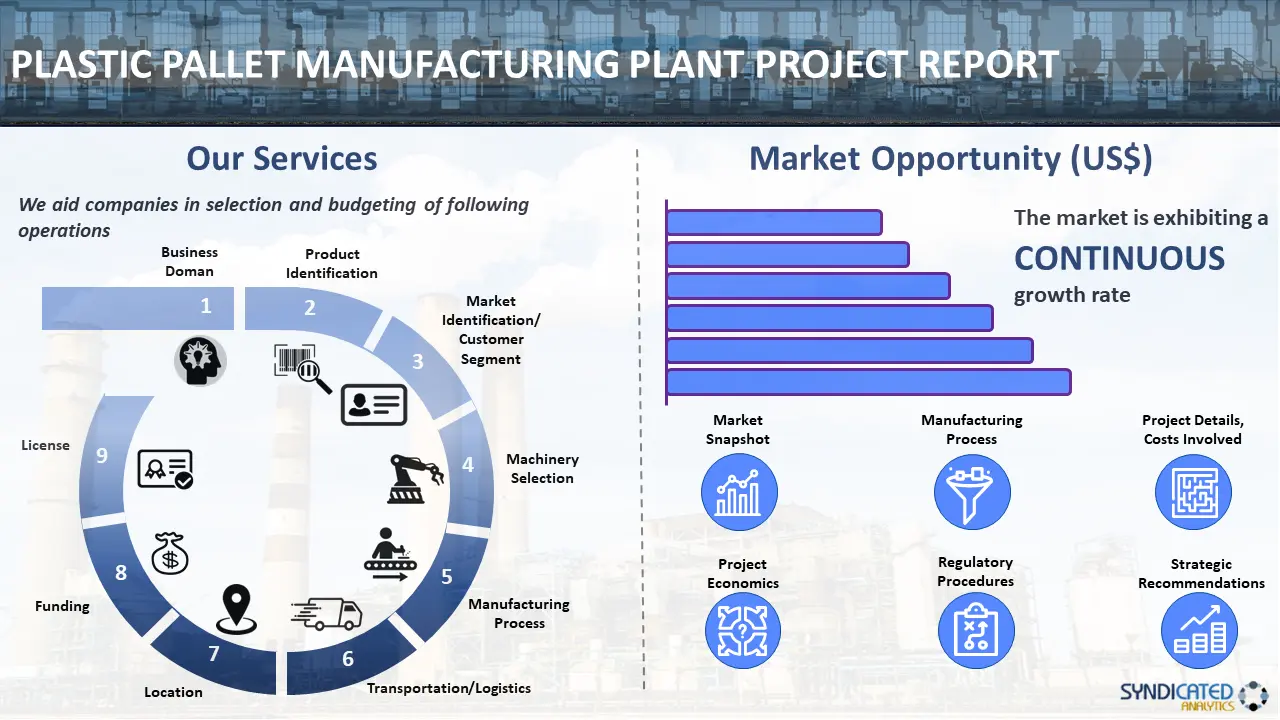

Report Coverage: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost (Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities

Report Overview:

Syndicated Analytics report, titled “Plastic Pallet Manufacturing Plant Project Report 2025 Edition: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost ( Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities” provides a complete roadmap for setting up a plastic pallet manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc. This report is a must-read for entrepreneurs, investors, researchers, consultants, and business strategists with a stake in the plastic pallet industry. It provides an in-depth analysis of the industry's current state and future potential, offering valuable insights for decision-making and strategy development. The report is an indispensable resource that offers a detailed examination of the plastic pallet industry. It is a valuable tool for anyone seeking to establish a foothold in this dynamic sector.

A plastic pallet is a durable, hygienic, and lightweight platform used to support goods while they are being stored or transported. Made from various plastic materials, including high-density polyethylene (HDPE) and polypropylene (PP), these pallets are known for their strength and resilience. They are an eco-friendly alternative to wooden pallets, as they can be cleaned, reused, and recycled more effectively, thereby reducing waste. Plastic pallets are often preferred in industries that require high standards of cleanliness, such as pharmaceuticals and food and beverages, because they do not harbor pests or fungi and can withstand extreme temperatures and exposure to chemicals without losing integrity. Their uniform size and shape also allow for better space utilization in storage and transport, making them a cost-effective option in the long term.

Market Trends/Drivers:

The global plastic pallet market is driven by the rise in hygiene standards across industries like pharmaceuticals, food and beverage, and electronics, which has significantly increased the demand for these pallets. These industries require stringent hygienic conditions for the storage and transportation of goods to prevent contamination, and as plastic pallets can be easily sanitized, they offer an optimal solution. Additionally, the growth in international trade has necessitated durable and long-lasting transportation solutions. Plastic pallets, with their superior durability over wooden alternatives, have become a staple in export-oriented businesses. They reduce the risk of goods being damaged due to pallet failure and are impervious to pests, which eliminates the need for fumigation and complies with international shipping standards. Another driving force is the shift towards sustainability and environmental responsibility. Plastic pallets are often made from recycled materials and are, in turn, recyclable, contributing to a circular economy and reducing the overall environmental impact of shipping pallets. As more companies adopt green practices, the appeal of plastic pallets is increasing. Moreover, automation in warehousing and manufacturing processes is also propelling the plastic pallet market forward. Automated systems require uniform and consistent pallet dimensions to function optimally, and plastic pallets fit these requirements. The precision and uniformity they offer, combined with their compatibility with various handling equipment, make them advantageous for businesses moving towards automated processes.

The project report covers the following aspects of the plastic pallet market:

- Market Snapshot:

- Market Performance

- Market Breakup by Segment

- Market Breakup by Region

- Price Trends

- Impact of COVID-19

- Market Outlook

- Manufacturing Process:

- Product Overview

- Detailed Process Flow

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Project Details, Requirements and Costs Involved:

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Expenditures

- Raw Material Requirements and Expenditures

- Packaging Requirements and Expenditures

- Transportation Requirements and Expenditures

- Utility Requirements and Expenditures

- Manpower Requirements and Expenditures

- Project Economics

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Profit Projections

- Financial Analysis

- Regulatory Procedures and Approval

- Key Success and Risk Factors

Key Questions Answered in This Report?

- What are the key success and risk factors in the plastic pallet industry?

- How has the plastic pallet market performed so far and how will it perform in the coming years?

- What is the structure of the plastic pallet industry and who are the key players?

- What are the various unit operations involved in a plastic pallet manufacturing plant?

- What is the total size of land required for setting up a plastic pallet manufacturing plant?

- What are the machinery requirements for setting up a plastic pallet manufacturing plant?

- What are the raw material requirements for setting up a plastic pallet manufacturing plant?

- What are the utility requirements for setting up a plastic pallet manufacturing plant?

- What are the manpower requirements for setting up a plastic pallet manufacturing plant?

- What are the infrastructure costs for setting up a plastic pallet manufacturing plant?

- What are the capital costs for setting up a plastic pallet manufacturing plant?

- What are the operating costs for setting up a plastic pallet manufacturing plant?

- What should be the pricing mechanism of a plastic pallet?

- What will be the income and expenditures for a plastic pallet manufacturing plant?

- What is the time required to break-even?

Need a Customized Project Report?

Although we have tried to make the report as comprehensive as possible, we believe that every stakeholder may have their specific requirements. In view of this, we can customize the report based on your particular needs. You can share your business requirements with our consultants, and we will provide you a tailored scope. Some of the common customizations that our clients request us include:

- The report can be customized based on the country/region that you plan to set up your plant.

- The manufacturing capacity of the plant can be customized based on your requirements.

- Machinery suppliers and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why buy Syndicated Analytics reports?

-

Our reports provide stakeholders insights into the viability of a business venture, allowing them to take informed business decisions.

- We have a strong network of consultants and domain experts in 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- We have a strong database of equipment and raw material suppliers across all major continents.

- We regularly track and update land costs, construction costs, Utility costs, labour costs, etc across 100+ countries around the globe

- We are the trusted business partners to the world’s leading corporates, governments, and institutions. Our client list ranges from small and start-up businesses to fortune 500 companies

- Our strong in-house team of engineers, statisticians, modelling experts, charted accountants, architects, etc. have been instrumental in building, expanding, and optimizing sustainable manufacturing plants across the globe.

Purchase Options

Ask For Customization

Personalize this research

Triangulate with your own data

Get data as per your format and definition

Gain a deeper dive on a specific application, geography, customer or competitor

Any level of personalization

Get in Touch

Call us on

US: +1-213-316-7435

Uk: +44-20-8040-3201

Drop us an email at

sales@syndicatedanalytics.com